How to refurbish Curved Screens

02 Aug

Posted By

1 Comment(s)

10846 View(s)

The people now know refurbish Samsung Edge screens can make more profits than refurbish iPhone screens, but it seems it is very difficult to refurbish curved screens, and some people even don't know how to refurbish curved screens, please don't worry, PartsFixit team share with you some tips and good machines to refurbish curbed screens now.

When you refurbish iPhone screens, you may all familiar with how to use a heating plate and alloy wire to separate the broken glass, if you are good at this step, you may still to use the same way to separate the curved screens, just take care to use very thin wire. But we have another better way to do it, it uses the Frozen Separator Machine, it is an easier and safer way.

Usually, if you just separate the glass for curved screen, just request the frozen separator machine can reach -145℃ ~ -150℃ is ok, Frozen Separator Machine is a big size and heavy package, so just select a middle one is ok, can save much shipping cost for you, but also can works.

TBK-578 Frozen Separator Machine is the recommend one by us, it can reach -175℃, and weight less than 70KG after packing, you can see the machine details by below picture.

This Frozen Separator Machine can display the current temperature, time countdown and room temperature on the touchscreen, when the current temperature reaches -175℃, you can put the screens in, and close the door, set the time countdown at 90 seconds, then start it.

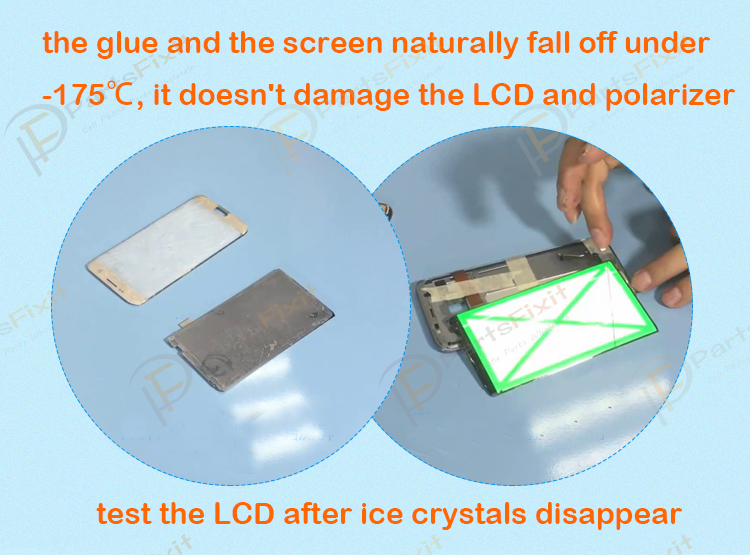

The glue and the screen naturally fall off under -175℃, it doesn't damage the LCD and polarizer, when the time is over, the machine will automatically whistle, then you can open the door to take out the screen, then you can easily open the screen glass with a plastic card.

Note: test the LCD after ice crystals disappear

Warm tips: if you just want to separate the glass and keep the frame on LCD, then set the Frozen Separator Machine temperature at -150℃, because the glass first fall off under this temperature, when the temperature is around -175℃, then the frame will fall off too.

kodecube.com

After separate the glass, you need to clean the glue on LCD, the glue remover may help you a lot.

This glue remover special design for the LCD glue removing, no need to change the needle, can work for half an hour.

Now, this red glue remover was upgraded to the blue one, please refer to below picture.

After cleaning the glue on LCD, you need to put the OCA on new glass, the special mold will help you in this step.

You can see the detailed operation video on our site. CLICK HERE FOR VIDEO.

Warm tips:

If you don't remove the frame for the curved screen, then suggest you use 200um or 250um OCA.

But if you already removed the frame, then it is better to use the thinner OCA, maybe 100um or 125um OCA.

The last important step is for vacuum laminating, you better use the professional curved screens laminating machine, OM-K6 Edge machine is the recommend one.

It works by soft airbag lamination way, with high security for both LCD and Flex cable, this machine not only can laminate the curved screens, it also works perfect for flat screens, includes LCD and OLED screens.

Using this machine and the compatible molds, you no need the OCA Film laminating machine anymore, also no need the roller. This machine can laminate the OCA on the glass, and also can laminate the glass with OCA on LCD. It also has the independent autoclave for bubble removing.

In short, using good machine can make your work easy, and make much money for you.

Let's share with each other to make work easier!

1 Comment(s)

Our top-tier professionals provide an elite, highly confidential, and luxurious experience where every detail is tailored to perfection, ensuring maximum relaxation, comfort, and satisfaction.

Leave a Comment